|

Mesoscale simulation of dislocation dynamics in relation with TEM observations |

Email-me at

douin@cemes.fr

Email-me at

douin@cemes.fr |

Simulations of dislocation dynamics are undergone at a scale which allows to include fine properties of the dislocations, as their tendency to dissociate for example. Emphasis is made on comparing results of the simulation with observations by up-to-date Transmission Electron Microscopy. In fine, calculations will include additional forces on dislocations as a result of their interaction with the free surface in order to study dislocation motion in thin foils and correlate them to in situ straining TEM. |

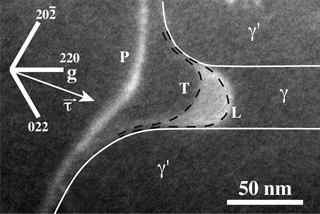

Dissociated dislocations in confined plasticity ref: publi 58

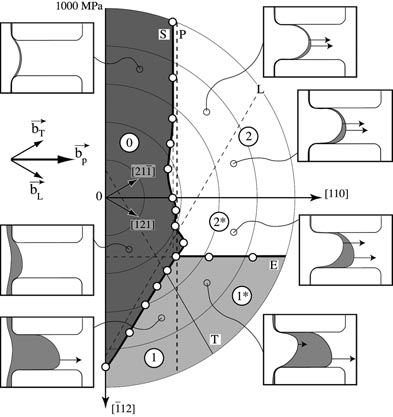

Weak-beam micrograph of a a/2[110] dislocation dissociated into two Shockley partials (L and T) trapped in a channel of a deformed MC2 superalloy. The gamma' precipitates are out of contrast and delimited by the white lines. The width of the channel is approximately 40 nm and the channel is oriented along the [110] direction. The dislocation noted P is a perfect dislocation fully located in the gamma-phase.Corresponding simulation: the effective shear stress is 450 MPa, oriented at 20° from [110] |

Critical stresses for the different types of b ehavior of a dissociated [110] dislocation moving in a (A111) plane of a MC2 alloy, as a function of the effective shear stress.

|

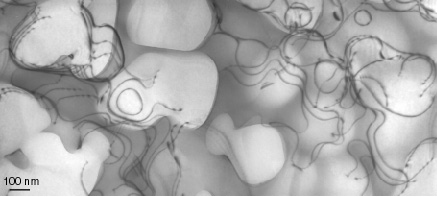

Dislocations in gamma / gamma' superalloys ref : unpublished results

Micrograph of a deformed NR3 superalloy (Raujol et al.)

|

Simulation of a perfect dislocation through a bimodal distribution of precipitates, either sheared or bypassed by the Orowan process |

Interaction dislocation / precipitate in Al-6056 alloy ref : publis 33, 36, 38, 39, 41, 42

High resolution TEM image of a lath-shaped precipitate

|

Simulation of the interaction dislocation / lath-shaped precipitate attesting of the shearing of the precipitate |

Interaction dislocation / precipitate in Al-5056 alloy ref : publis 33, 36, 38, 39, 41, 42

Bypassing of the rod-shaped precipitates by Orowan process. |

|